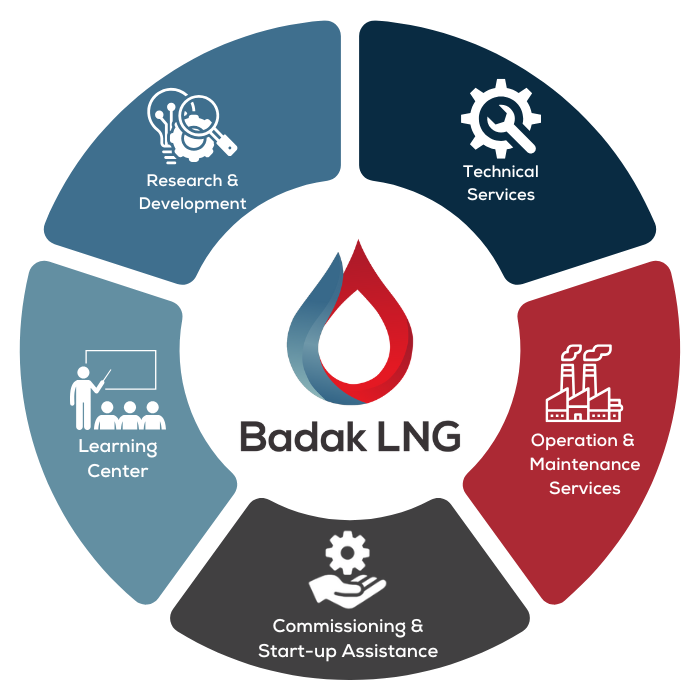

Our Services

Technical Services

Our team are proficient in providing technical services, including troubleshooting and repair, and feasibility studies, FEED, DED and EPC. Learn More..

Operation & Maintenance

Ranked first in plant reliability by a global industry benchmarking institution, we provide this all-inclusive service to support the operation & maintenance of LNG companies worldwide. Learn More..

Commissioning & Start-up Assistance (CSUA)

As commissioning & Start-up holds an important role in LNG Plant, we assist LNG companies in ensuring the preparedness of plant facilities, process and system altogether, for a smooth-running operation. Learn More..

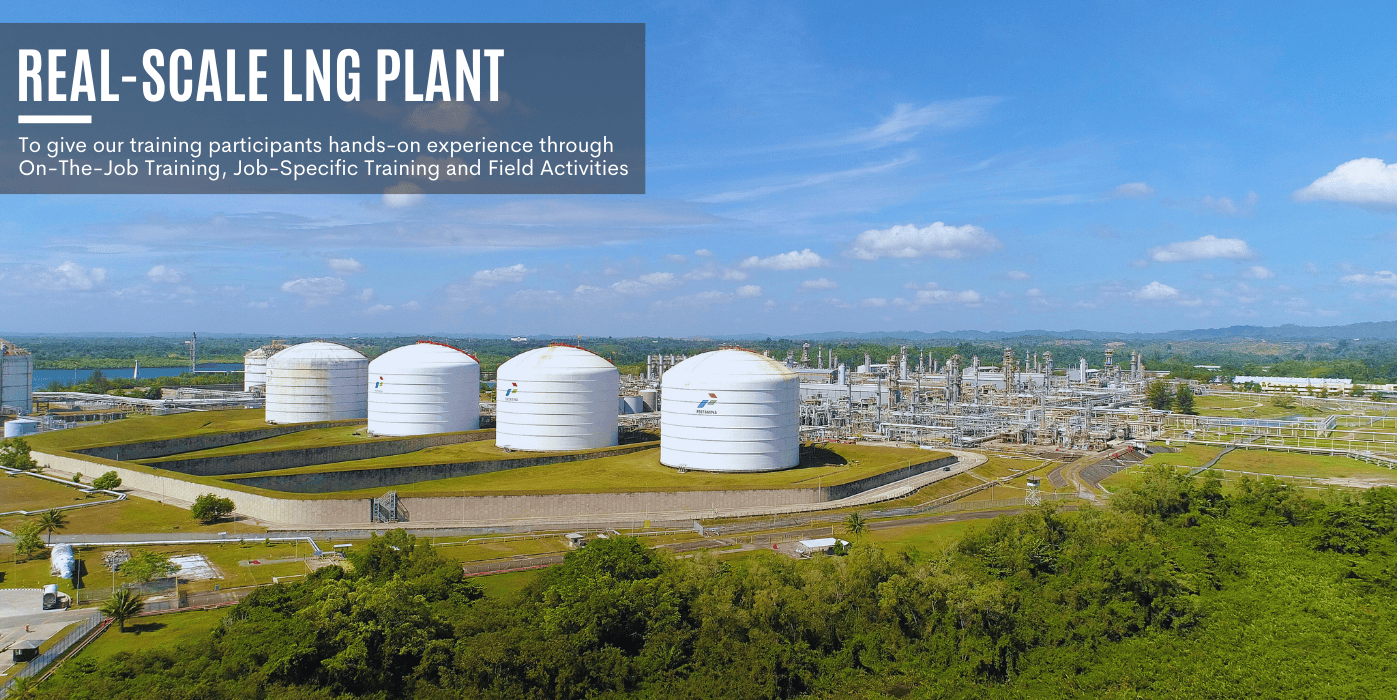

Learning Center

Our training programs are specifically designed to prepare professional LNG Plant Operators, Technicians and other key actors in the LNG industry. Training syllabus is customizable as specified by our clients. Learn More..

Research & Development

The emerging technology encouraged us to continuously innovate and look for solutions to tackle operational challenges. We conduct various studies, such as lean gas study, dual HHV study, mini-LNG plant, hybrid power plant, etc. Learn More..

Our Facilities

Technical Services

Our highly experienced team are keen to provide troubleshooting and repair service for LNG plant & LPG gas facilities.

We conduct feasibility studies, including conceptual design, commercial study, legal and studies that are related to engineering compliance standards.

LNG Plant Operation & Maintenance (O&M)

Earned a reputation as the most reliable LNG Plant emphasize our competences and credibility in the industry. Therefore, we provide this all-inclusive service to support the operation & maintenance activities of LNG companies worldwide.

Our O&M Service includes:

- Troubleshooting & Repair, both on-site (in situ) and off-site

- Operation of LNG Plant, LPG Plant, Gas Processing Facility, Regasification Facility, LNG Terminal, etc.

- Development of maintenance management system

- Organizational structure design and manpower planning

- Development and implementation of Safety, Health, Environment & Quality (SHE&Q) management system for a reliable and safe plant management

- Development and implementation of Maintenance Programs to maintain train availability and reliability

- Run/operate train professionally and conduct continuous improvement to enhance train efficiency

- Development and operation of other supporting systems, such as: marine operations, security management system, spare part management, HR management system, IT management system, etc.

Commissioning & Start-up Assistance (CSUA)

Commissioning & Start-up phase verifies and validate all equipment work properly and harmoniously, as well as meets both performance and safety standards. Our teams are ready to assist you in the execution. This service also includes Operational Readiness stage that covers not only technical aspects, but also policy aspects.

Our CSUA clients are including Angola LNG, BP Berau Ltd. (Tangguh LNG), Cameron LNG, Freeport LNG, FPU ENI Jangkrik, Pertamina RFCC Cilacap, and Woodfibre LNG.

Commissioning & Start-Up Assistance

- Client assistance to ensure a smooth plant pre-commissioning & commissioning process

- Client assistance to conduct a safe plant start-up

- Providing advisory during commissioning or start-up process to prevent re-work and ensure a smooth-running process

- Development of commissioning procedure as well as a safe and reliable start-up and shutdown procedure

The Operational Readiness divided into:

-

Policy Aspects, covering philosophy, Human Resources (HR), commissioning strategies, and division authority between EPC contractor and project owner.

-

Technical Aspects, including the Standard Operating Procedure (SOP) derived from policy aspects.

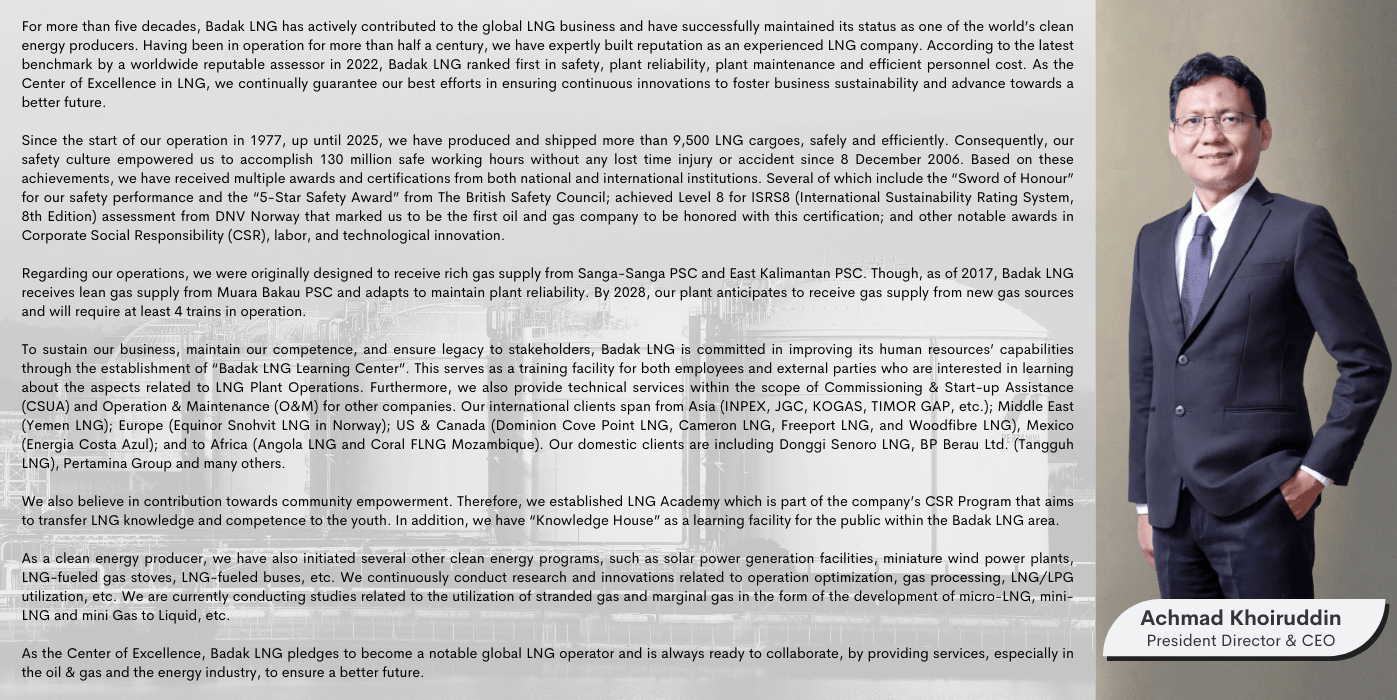

LNG Learning Center

LNG Plant Operator Training

An 18-months intensive program divided into 3 sessions: In-Class Courses(3 months), On-the-Job Training (3 months), Job-Specific Training at Plant Operation Area (12 months).

The program can be customized based on client’s need. Graduates will be ready to work as field operators in LNG Plant.

LNG Plant Maintenance Training

An 18-months intensive program, divided into 3 sessions: In-Class Courses (3 months),On-the-Job Training (3 months), Hands-On Maintenance Training (12 months).

Clients may customize training syllabus to comply with clients' specific requirements.

Training graduates are expected be ready to work as technicians/mechanics in LNG Plant.

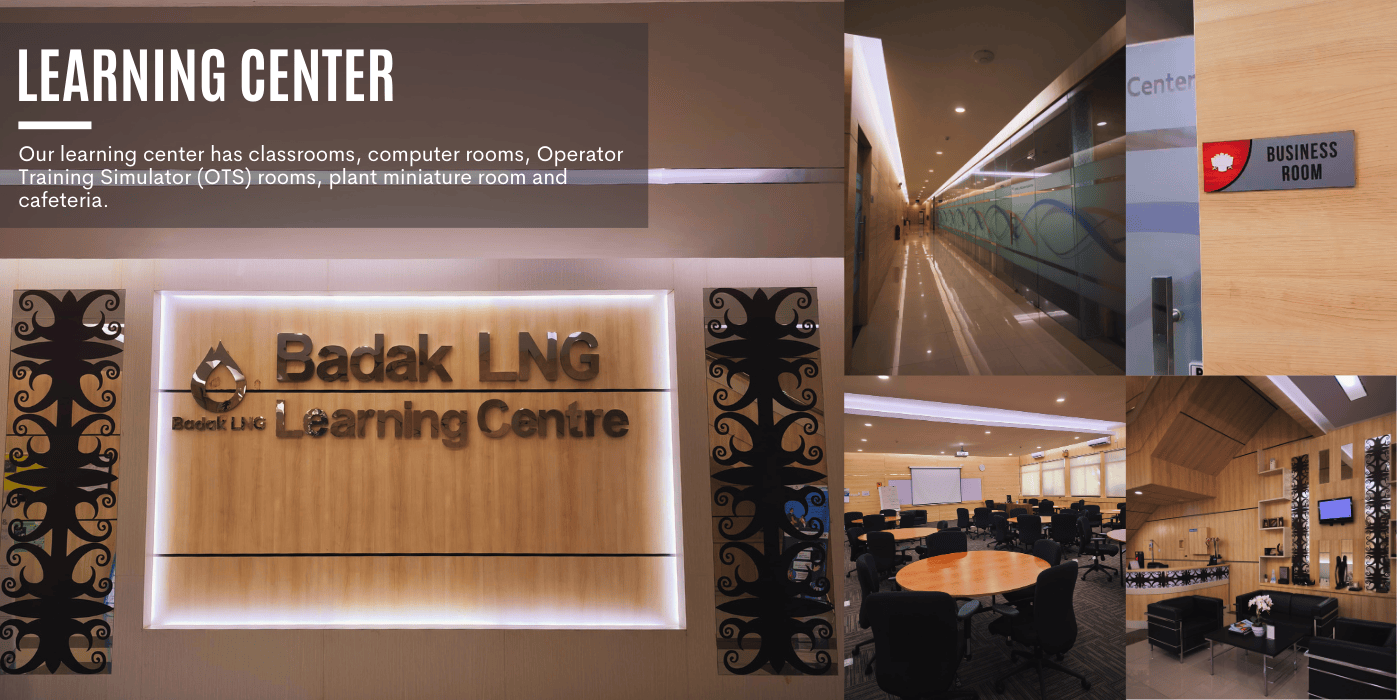

LNG & Hydrocarbon Firefighting Training

Badak LNG has proven a great success in training competent firefighting personnel with this program.

Our years of experience allows us to offer the opportunity for firefighters from other companies to enhance their competences through real LNG firefighting scene.

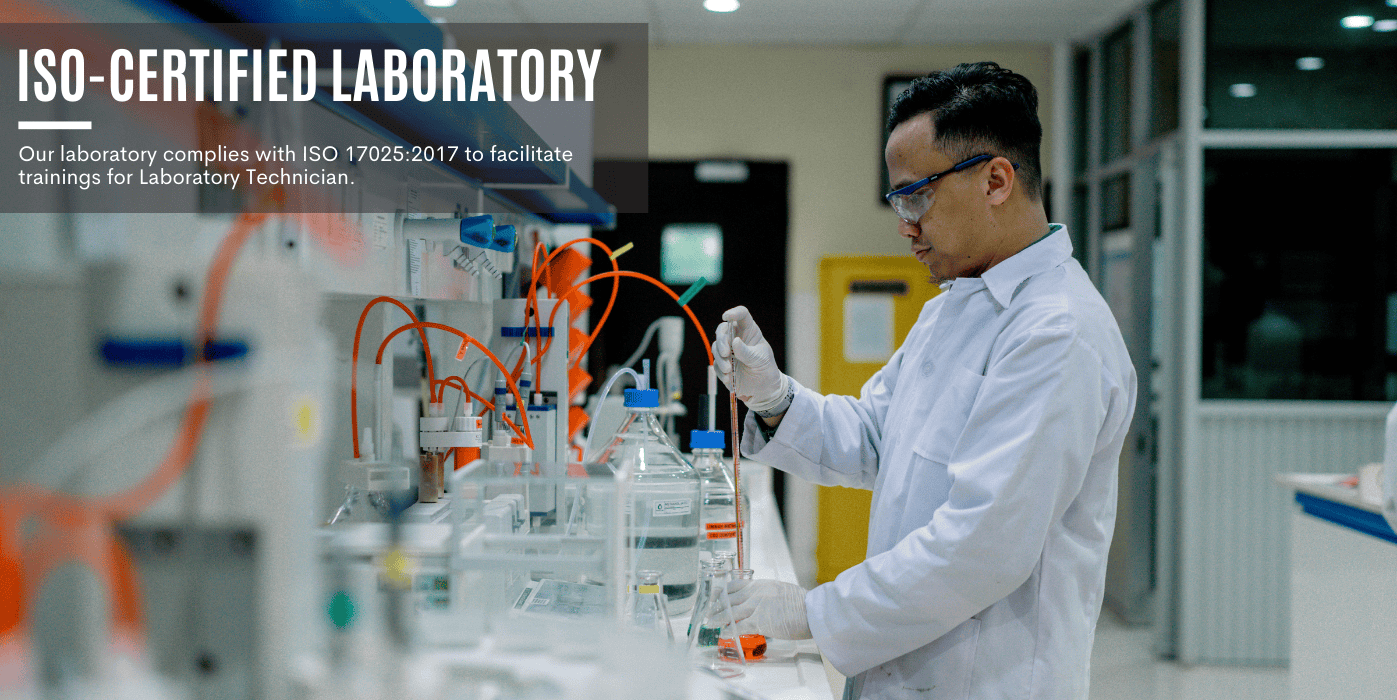

Laboratory Analysis Training

Badak LNG provides training programs for Laboratory Analyst, that includes: ISO 17025, Gas Chromatograph, Atomic Absorption Spectrometry, High Performance Liquid Chromatography, and Sampling Method.

LNG Plant Turnaround Training

Plant Turnaround, or Shutdown, is essential to maintain the reliability of plant operation.

With broad experience in shutdown executions with satisfactory results, we develop training programs to train personnel to be qualified in shutdown/turnaround execution.

LNG Plant Production Planning Training

This training program aims to facilitate and equip participants that to carry out production planning that takes a broader look, from upstream to buyer.

Marine Operation Training

This training program covers the operation of marine facilities which consists of onshore facilities (ports, jetties, and loading dock) and offshore facilities (sea signs, tugboats, and mooring boats).

Badak LNG’s marine facilities have complied with ISPS (International Ship and Port Security) code and have been used to conduct trainings related to the compliance with ISPS port management system.

Tugboat & Mooring Boat Docking Maintenance Training

Badak LNG has carried out docking for tugboats and mooring boats since 2013 at a dockyard built in Badak LNG area.

The system developed by Badak LNG is valuable for companies that own tugboat and mooring boat facilities.

Professional Certification Agency

Research & Development

The complexity of Lean Gas supply to Badak LNG encouraged us to innovate in modifying our plant to extract more LPG products, by installing a new cooling system to the scrub column. This modification was carried out in two of our trains that are currently still in operation, Train G and Train H.

Supporting the Government of Indonesia’s program in renewable energy, Badak LNG has initiated the small-scale hybrid renewable energy project. This project is a combination of Wind Power and Solar Panel with a total capacity of 2,000 W.

Micro LNG Plant

Badak LNG conduct a research to develop Micro LNG Plant with a capacity of less than 1 MMSCFD as a strategic project to seize the future business opportunity: the optimization of flare gas or processing natural gas in small gas field.

Dual HHV

The Lean Gas supply to Badak LNG Plant raises an issue of LNG HHV reduction, which potentially may not be able to meet the specification in the existing contract. Badak LNG successfully managed this condition by transforming the plant operation from Single HHV production to Dual HHV with two LNG product quality. This process modification is the first in the world.

Badak LNG cooperates with Chiyoda International Corp. (CIC) and Enerproco LLC to establish a joint-venture company named Badak Chiyoda Enerproco, LLC (BChE) to deliver our services to clients in North America (USA, Canada & Mexico) that need US entity for administration purpose. The clients we serve with BChE includes Cameron LNG and Freeport LNG.

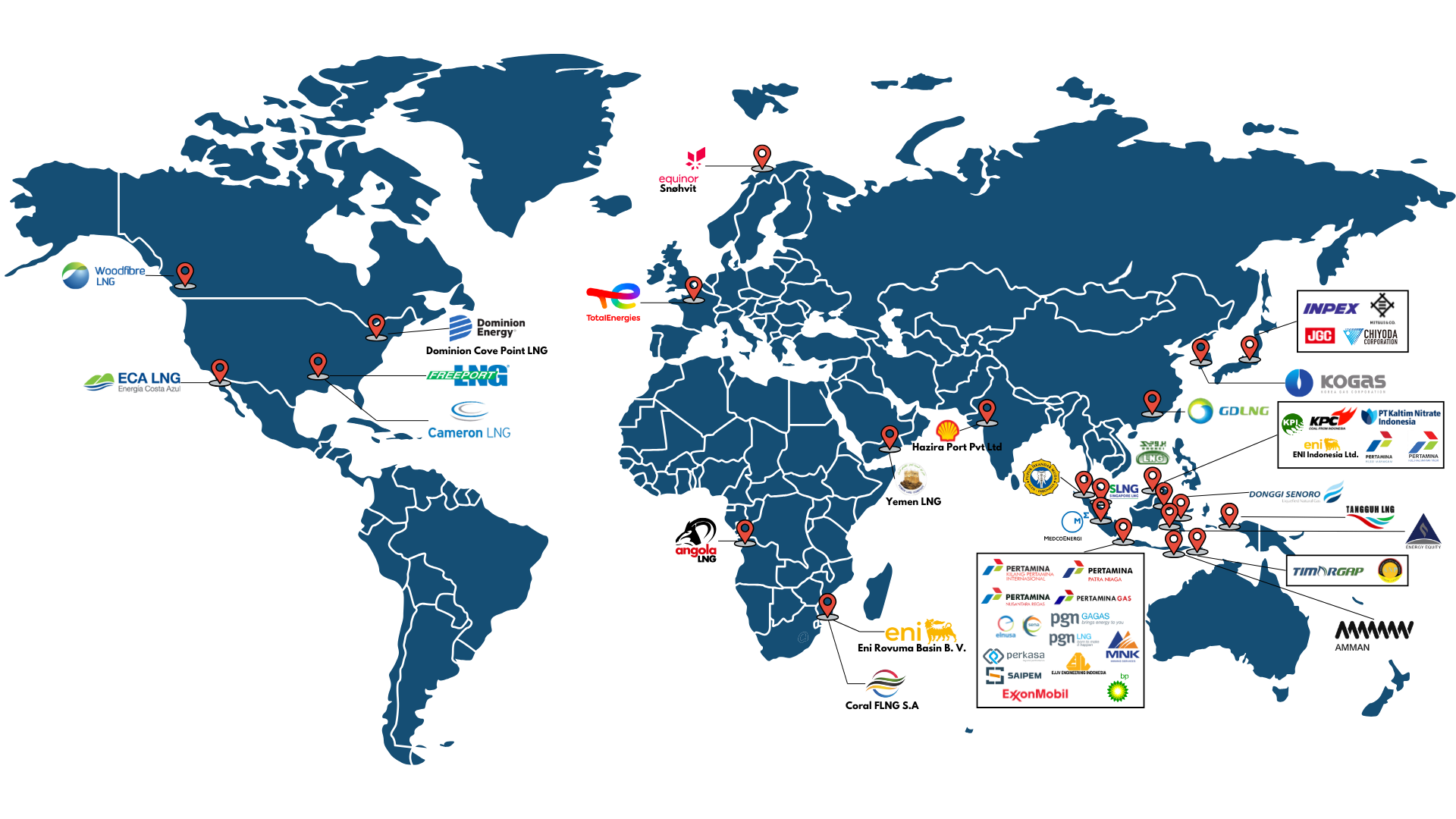

Our Clients

Jakarta Office

Wisma Nusantara 9th Floor

Jl. MH Thamrin No. 59

Jakarta 10350

Indonesia

T : +6221 3193 0243

Bontang Plant Site

Bontang 75324

East Kalimantan

Indonesia

T : +62 548 55 1300

+62 548 21 133 (4 lines)

F : +62 548 27 500

Balikpapan Office

Jl. Jend. Sudirman No. 66

Balikpapan 76101

East Kalimantan

Indonesia

T : +62 542 764 671